Euro pallets, also known as EUR pallets or EPAL pallets, are a standardised type of pallet widely used in logistics and transportation.

EPALs are crucial for managing, storing and shipping goods. They offer many advantages, such as improving efficiency and promoting safe handling and storage.

The advent of Euro pallets has transformed the logistics industry, making it imperative for anyone in this field to have a solid grasp of their function.

Development of EPAL pallets

The origin of EPAL pallets can be traced back to the 1950s. In that period, European countries recognised they could improve their transportation industry. They realised it would be much more efficient and organised with a common pallet size.

Countries like Germany, France, and Belgium were the first to show interest in creating that product. In 1961, they established EPAL as an international association to create a standardised pallet system. They determined the standard measurements of the pallet, which ensured compatibility with different transportation modes and warehouses. Furthermore, they established their certification and standards, followed by common construction materials.

Their pallets were versatile and remarkable in quality. Hence, the Euro pallet system quickly spread throughout Europe. More and more companies started using them and noticed a massive increase in their efficiency.

Europe had a major upgrade in its transport and logistics operations. That led to international companies also starting to use EPAL pallets. Naturally, their versatility and quality was an important factor. But they also found it more convenient to have a standardised pallet compatible with the European logistics system.

EPAL collaborated with national pallet organisations globally, resulting in the establishment of EPAL-licensed production and repair facilities in various countries. This network of authorised manufacturers guarantees the availability of high-quality EPAL pallets worldwide.

EPAL pallet – specifications and dimensions

-

Standard dimensions

The standard dimensions of a Euro pallet are:

- length – 1200mm

- width – 800mm

- height – 144mm

These dimensions are optimised to fit in trucks and storage systems in Europe. EPAL has strict quality control measures to ensure that Euro pallets meet the required standards. However, there might be slight changes in their dimensions in certain regions. Plus, they may have additional features or modified dimensions for specific needs.

-

Material and construction requirements

Euro pallets are usually made out of softwood like pine or spruce. They have multiple deck boards that run parallel to the length of the pallet.

Between those deck boards, blocks or stringers support the load. They use nails or screws to hold everything together. Euro pallets undergo certain treatments to ensure their quality. The most common is heat treatment to eliminate pests and sterilise the wood.

-

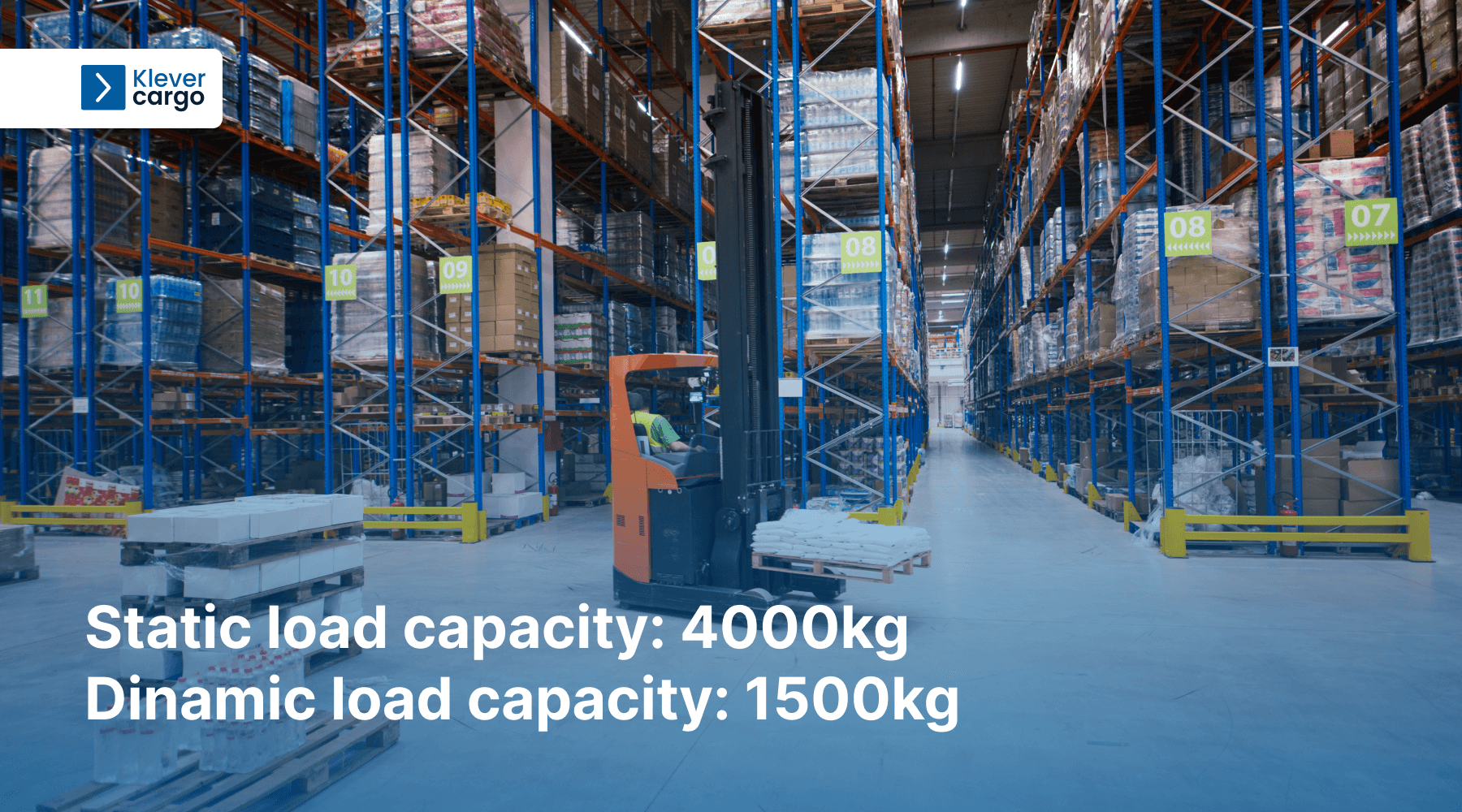

Load capacity and weight limit

Euro pallets have specific load capacity and weight limit guidelines set by EPAL to ensure the safe and efficient handling of goods. There are two different weight limits for Euro pallets – dynamic and static.

When using a forklift or other handling equipment to move a Euro pallet, knowing the maximum weight the pallet can safely support is important. This is called the dynamic load. The Euro pallet has a dynamic load capacity of 1,500 kg.

A Euro pallet can hold up to 4,000 kg of weight when not in motion. This weight limit is known as the static load capacity.

Quality control of EPAL pallets

-

EPAL certification process

There is a strict process that goes into becoming EPAL certified. The process looks like this:

- comply with EPAL standards (dimensions, construction materials, and the like);

- application and audit (EPAL has audits to verify the quality requirements);

- marking and identification (approved pallets will get a logo stamp and identification number);

- license and membership (manufacturers that meet the requirements will get a license for producing and selling pallets);

- regular inspections and audits (EPAL will regularly check the manufacturers to ensure they keep the standards).

-

Quality standards

In order to meet quality standards, the European Pallet Association has established strict rules and guidelines. Manufacturers who wish to produce Euro pallets must obtain a licensing agreement to ensure their compliance with EPAL’s standards. These standards cover various requirements, including dimensions and materials verification.

Next, the manufacturer must maintain a quality control system that constantly monitors the pallets’ quality. EPAL may conduct regular inspections to ensure compliance with their standards, and the manufacturer receives the official EPAL license once all requirements are met.

-

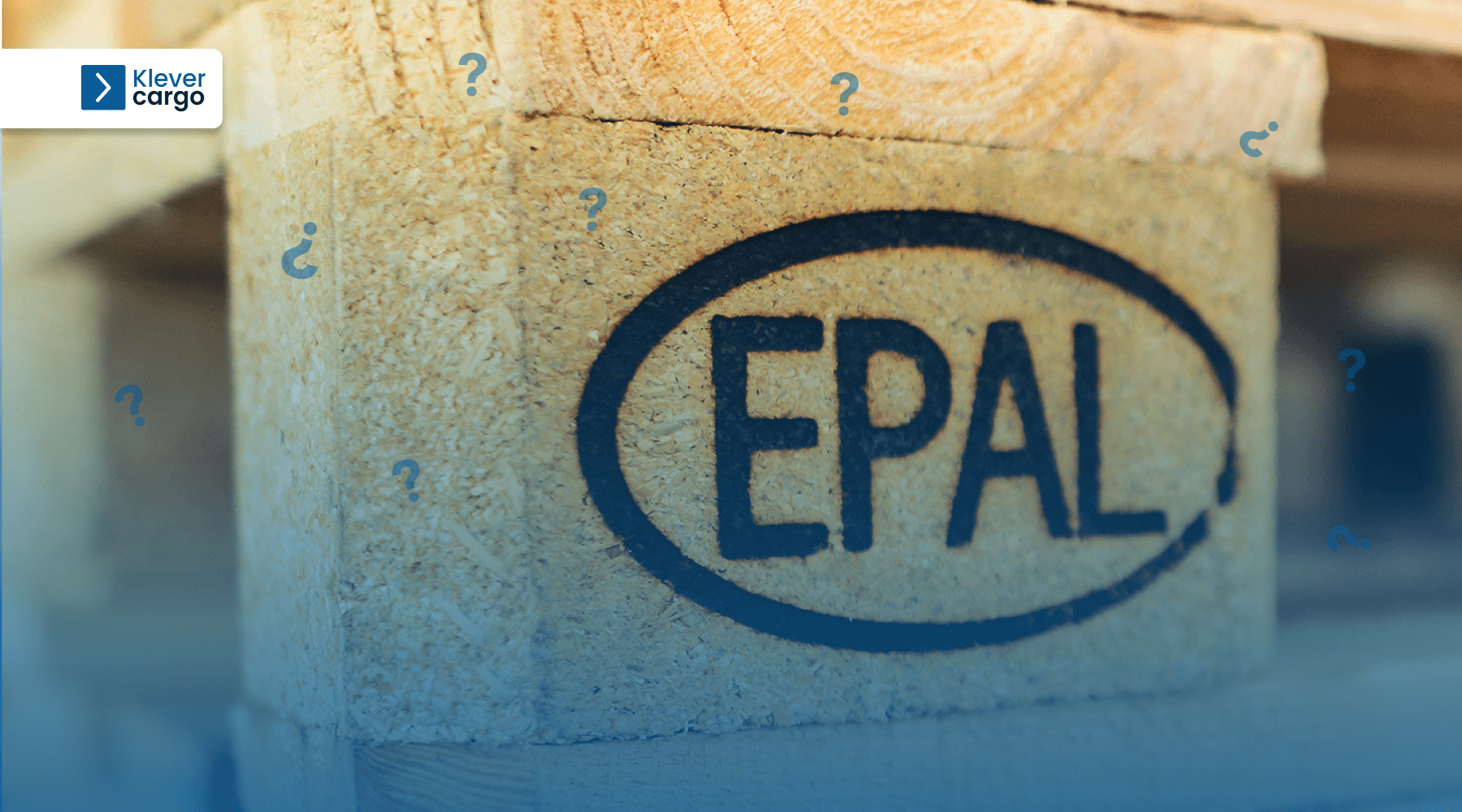

EPAL identification and markings

EPAL has its identification and markings to confirm its authenticity. That includes:

- EPAL logo;

- unique verification number;

- country code;

- IPPC marking;

- quality mark.

Customers can rely on these markings to ensure the consistent quality of Euro pallets within the EPAL system.

Difference between the other pallets and EPAL pallets

The main difference is that regular pallets vary in dimensions, construction, and quality. EPAL pallets have standardised dimensions, strict quality control, and specific markings confirming authenticity and compliance.

Pallets come in different sizes and materials depending on the industry they are intended for. They can be made from wood, plastic, or metal and have varying designs and construction methods. Some pallets have two-way or four-way entry to allow forklifts to access them from different sides. The level of reinforcement also depends on the load capacity requirements. Also, regular pallets will rarely go through quality control procedures. Hence, their overall quality and durability are questionable.

EPAL pallets always adhere to the same measurements of 1200x800x144, and the materials used to construct them are consistent, with specific wood types such as spruce or pine always being utilised. Euro pallets have unique design features that distinguish them from regular pallets, specifically intended to promote durability and safety during handling.

Examples of such features include precisely cut edges that prevent splintering, as well as unique nails used for assembly.

Finally, the most important difference between regular and Euro pallets is their quality control. Euro pallets undergo rigorous quality control procedures. With regular inspections and tests, there is no room left for malfunctions. The EPAL logo and a unique identification number make it easy to identify approved pallets. That means that the pallet complies with the quality criteria.

Advantages of EPAL pallets

-

Applicability in various industries

You can easily apply EPAL pallets in various industries. That’s possible because of their compatibility, versatility, and global recognition.

They’re made to be compatible with a wide range of handling and storage systems. As such, different industries can easily add them to their operations.

EPAL pallets have a significant advantage in their versatility. You can use them to transport various products, such as food, beverages, industrial equipment, and more. This convenience eliminates the need for companies to use different pallets for different products.

Their dimensions and quality standards are globally known. Hence they’re the first choice for countless industries across the globe.

-

Sustainability and recycling initiatives

Recyclable materials are used to make EPAL pallets, minimising their environmental impact. They are designed for durability and long-lasting use, resulting in less waste than single-use pallets.

EPAL pallets are designed to be repaired, so companies can easily fix and reuse them instead of discarding them. In cases where a pallet cannot be repaired or reused, it can be recycled. EPAL advocates for responsible recycling practices to ensure that all pallets are disposed of or recycled in an environmentally-friendly manner.

-

Handling and transportation friendly

With their standardised dimensions and stability, EPAL pallets are effortless to handle and transport. They are compatible with various handling machines, like a forklift or a racking system. They also fit perfectly in warehouses and transportation vehicles.

EPAL pallets are designed to be stable. You can easily stack and secure them without the risk of them falling over. Their design allows them to distribute the weight evenly, making it balanced and supported.

With these features, Euro pallets make loading, transporting, and unloading goods easy without risking damage.

This can be especially handy if you use a freight exchange platform like KleverCargo. This platform offers an open marketplace that helps you locate palletised cargo for transport, making it easy to connect with shippers or carriers who also work with EPAL pallets.

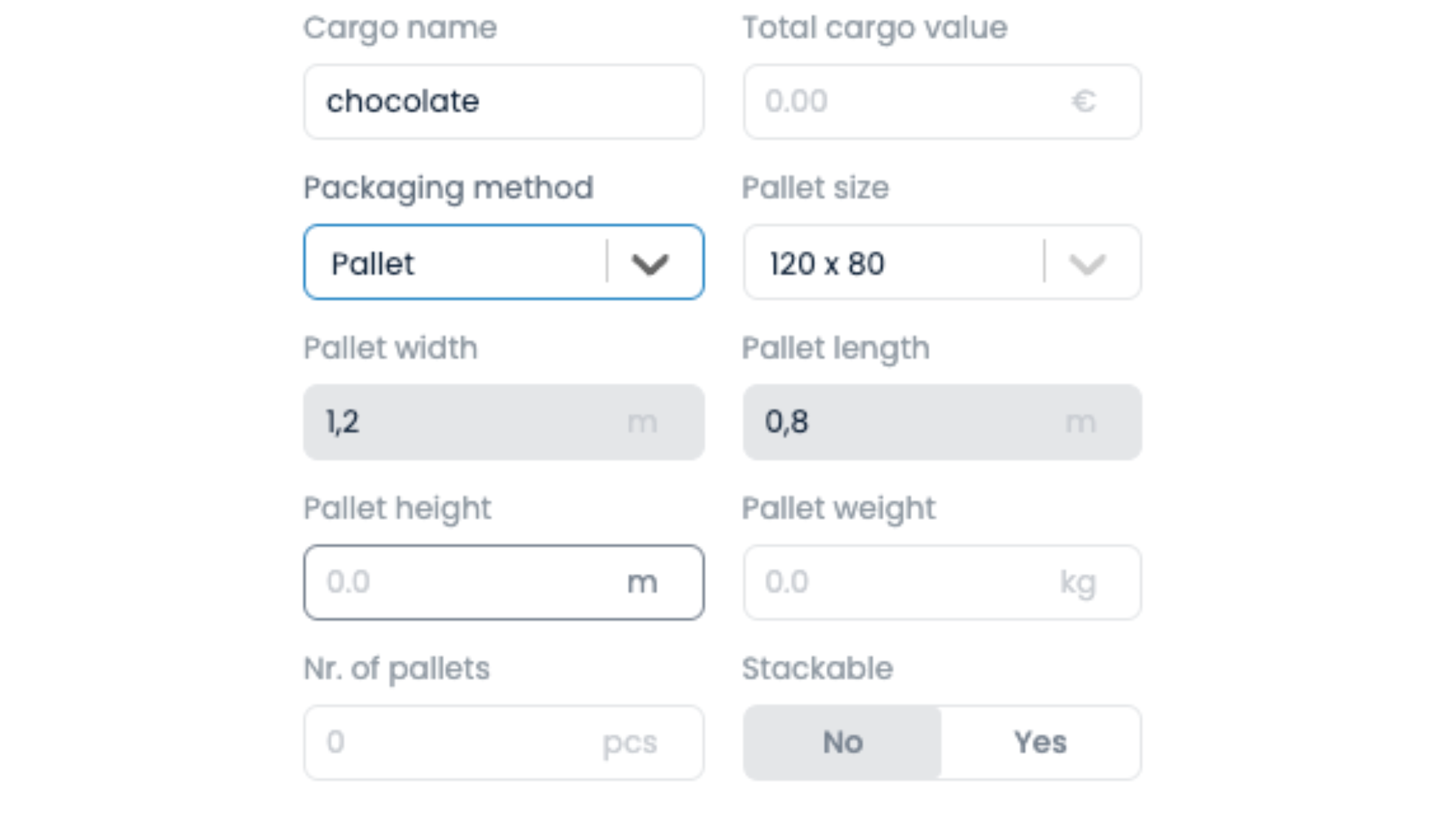

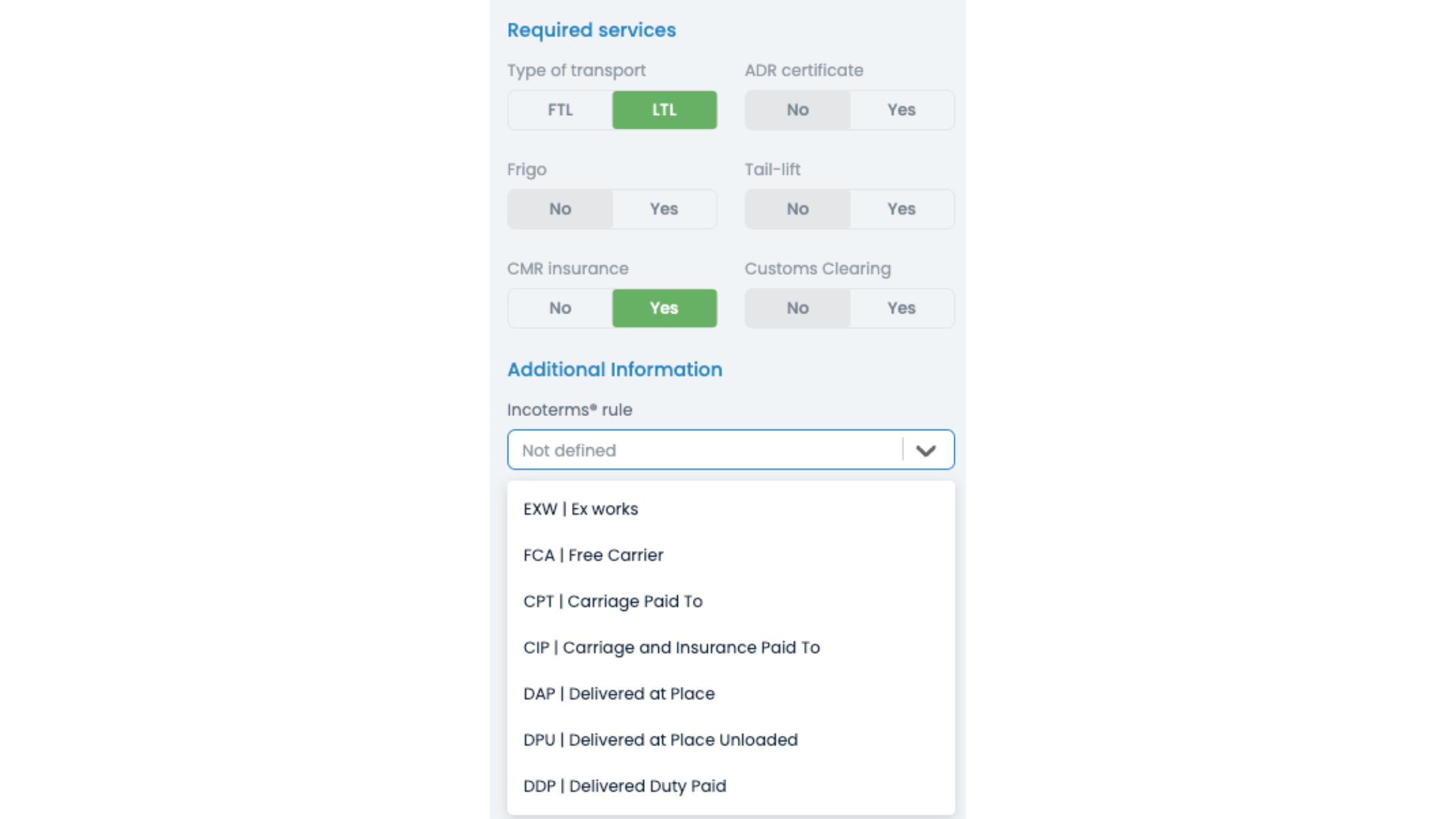

If you have palletised goods and need to find a reliable carrier, the process is pretty simple and can be done in a few simple steps:

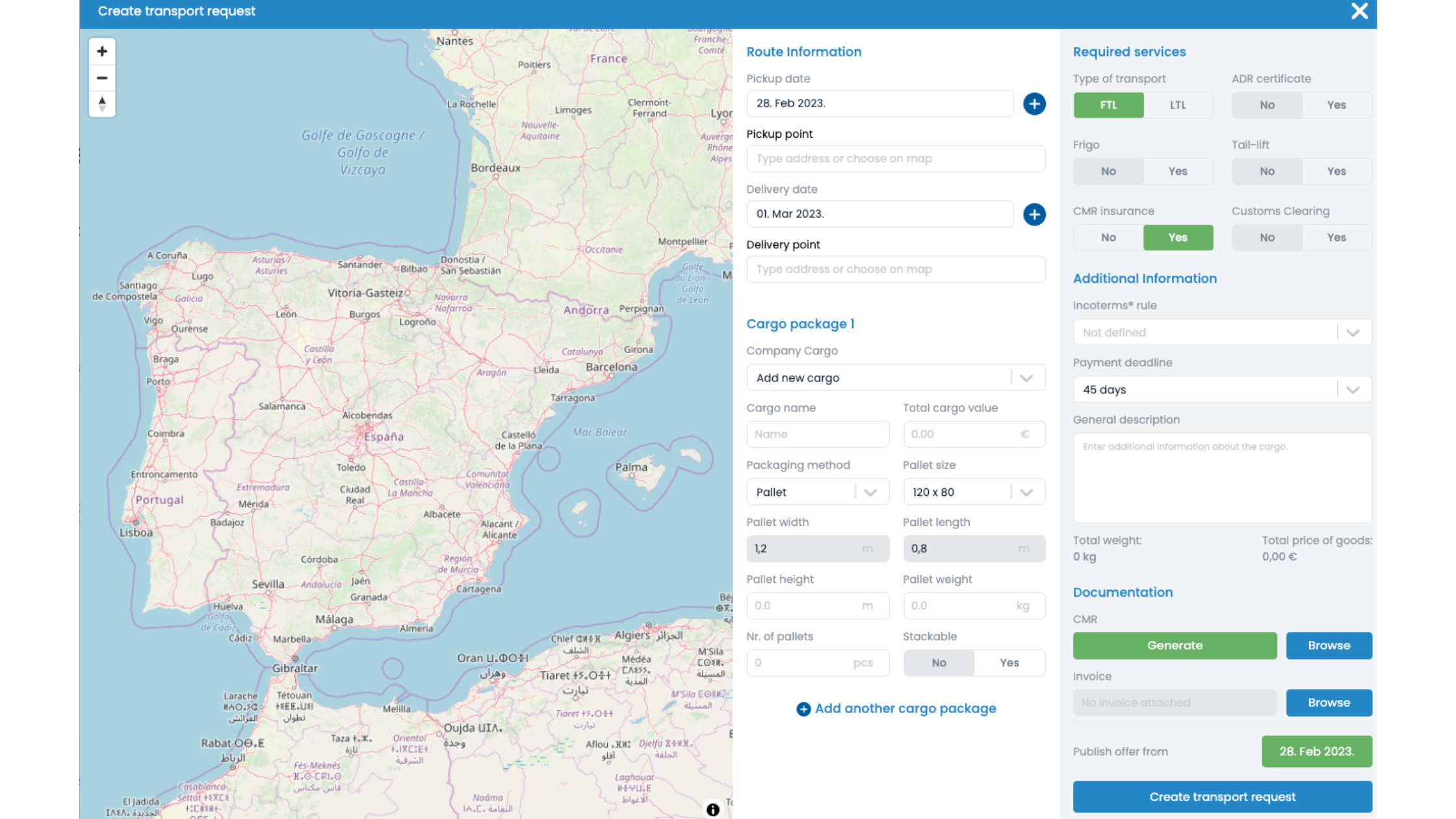

1.Select the Transport Request section to publish your cargo and find transport to the necessary location.

2. Clicking on the Transport Request icon will bring up a menu where you can input all necessary details about your cargo in order to receive the most suitable transport offer.

3. When adding a new cargo, selecting the appropriate packaging method is important. In this case, you should opt for the pallet.

4. To complete the process, locate the section that outlines the requirements for transporting your cargo – choose the appropriate ones and click the Create Transport Request button. That’s it.

Challenges of EPAL pallets

-

Repair and reconditioning of damaged pallets

Although the ability to repair the damaged pallets is an environmentally friendly approach, it does require additional effort.

With strict quality control, you must follow specific guidelines to repair the damaged pallet. The pallet will be rejected during inspections if you don’t follow these guidelines.

EPAL pallets can only be fixed in authorised repair facilities. This ensures that the repaired piece will maintain the quality standard since trained professionals handle the repairs. Finding one of those facilities can sometimes be challenging in certain areas.

Additionally, every repaired pallet must be documented to maintain its markings. This can also be challenging since it adds more paperwork and procedures.

-

Pallet shortage

People generally recognise EPAL as a standard type of pallet, and it’s not uncommon to experience a shortage due to its versatility across different industries.

The fact that only licensed manufacturers produce them is another reason for the shortage. There aren’t that many licensed EPAL pallet manufacturers. Hence they can’t handle all the demand, which is constantly increasing.

Additionally, EPAL pallets are geographically distributed. That means there will be more pieces in certain regions than in others.

-

Counterfeit and non-compliant pallets

Another challenge for both Euro pallet manufacturers and customers is counterfeit pallets.

Counterfeiters exploit the fact that the demand is high and that the market is under pressure to find EPAL pallets as soon as possible. They will bypass the standards and material requirements to profit by selling fake EPAL pallets.

This can be a huge problem for the customers since the counterfeit EPAL pallets won’t be nearly as good as the original pieces. Furthermore, this is also problematic for manufacturers since the lack of quality will result in numerous complaints. Of course, since the customers don’t know that these aren’t the original, that can damage the manufacturer’s reputation.

A most common question on EPAL pallets

-

How many Euro pallets is a full truckload?

A standard full truckload can accommodate 33 Euro pallets. That number may vary slightly due to the size and capacity of the truck.

-

How long do EPAL pallets last?

The average lifespan of a Euro pallet is around ten years or more with proper care.

-

Are EPAL pallets waterproof?

EPAL pallets are not waterproof since they are made from wood which can absorb moisture. However, waterproofing agents or sealants can enhance the EPAL pallets’ resistance to moisture.

-

What is the cost of the EPAL pallet?

A new EPAL pallet in Europe costs between €10 and €20 per pallet. The price can vary depending on the region, quantity, market demand, and other relevant factors.

-

How can you tell if a pallet is EPAL?

EPAL pallets have identification markings to help you determine whether a pallet is Euro. Those are:

- EPAL logo;

- IPPC marking;

- EPAL unique identification code;

- standard dimensions (1200x800x144);

- quality markings (EPAL or EUR stamp).

EPAL pallets are essential in logistics

Euro pallets are an essential part of the transportation industry with their convenience and quality. By using them, companies will have a reliable solution that meets all quality requirements.

These perks made them internationally popular, and using EPAL pallets became an industry standard. As in any other field of business, the goal is always to try to make things better organised and more efficient. And when you combine the usage of Euro pallets with an exceptional platform for transport and logistics, you will undoubtedly achieve that goal.

Embrace future trends and streamline your operations with simple and effective solutions.