The supply chain in the transportation industry consists of several specific areas that must work together to enable its smooth functioning. This includes suppliers, manufacturers, transport, retail and, of course, warehousing.

75% of people who use the Internet buy items online. As we witness the global rise of e-commerce, it’s clear that the demand for available storage space is also increasing.

Thankfully, advancements in technology and automation are continuously enhancing to meet customers’ growing expectations. Therefore, storage solutions will become even more efficient and accessible. This is why all transportation and logistics industry players must comprehensively understand it.

What is warehousing?

Warehousing is the process of storing goods before transporting them where needed. Goods are stored in specialised buildings called warehouses.

Warehousing is crucial in the transportation industry due to its convenience and security. It provides a secure location for businesses to store and organise their products, facilitating better inventory management. Additionally, warehousing ensures that products remain in optimal condition before transportation.

Another perk of warehousing is labelling and packaging products in a safe location. That makes it significantly easier to meet customer requirements.

Difference between warehouse and distribution center

The primary distinction between a warehouse and a distribution centre lies in their focus. While a warehouse concentrates on storing goods, a distribution centre receives, categorises, and transports goods to their ultimate destinations.

Warehouses usually handle the long-term storage of goods. This can come in handy if products aren’t immediately needed for distribution.

When it comes to distribution centres, speed and flexibility are crucial. These centres receive shipments, rapidly sort and process the products, and then distribute them as quickly as possible. Their goal is to fulfil orders promptly.

Another thing that makes them different from each other is their location. Companies will usually locate a warehouse where they’ll get a lower rent and be close to manufacturing facilities. Commonly, they’re far from the end customers.

On the other hand, distribution centres are usually placed in locations that make the distribution process easier and faster. They are often closer to major transportation routes and end-user markets, allowing swift and more cost-effective delivery.

5 warehousing processes

-

Inventory managing

Inventory management is an important process. It includes supervising the goods in a warehouse. Some of the most essential tasks that come with inventory management include:

- stock control;

- receiving and inspecting goods;

- storage and organisation;

- inventory tracking and monitoring;

- replenishment;

- inventory accuracy;

- stock optimisation.

With optimised inventory levels, there’ll never be too little or too much of a product. That makes it easy to meet customer demands.

Inventory management is crucial for any company, and barcode scanners and management systems are essential tools for achieving this. They provide real-time reports and enable companies to track inventory levels easily.

In addition, by analysing market trends, inventory managers can make better decisions. They have a better understanding of whether they should reorder certain products.

-

Receiving and put-away

Receiving and put-away involve getting and storing goods when they arrive at the warehouse.

When shipments are received, the warehouse workers will carefully inspect them. They will verify that the goods match the documents and then record the receipt in the inventory system. This process guarantees that the correct products are received in the appropriate quantities.

Once received, the put-away process begins, where warehouse staff allocate a designated spot for each item and organise them accordingly. This efficient method optimises the use of space and ensures easy accessibility when retrieving items.

-

Picking and packing

Picking and packing are the processes of getting items from storage and preparing them for shipping.

Picking means finding the right items in the warehouse. Workers follow the instructions and collect them in one place.

Once the items are picked, packing starts. Workers carefully put the items in boxes or envelopes and label them. Then, they protect the items and add any necessary papers.

Properly picking and packing will collect the right items and not get damaged during shipping. These jobs help deliver quick and accurate orders, making the warehouse run smoothly.

-

Shipping

Shipping is a crucial aspect of warehousing that involves preparing goods for delivery to customers or other destinations. Once the items are packed and ready, warehouse staff coordinate with shipping companies to arrange transportation. They then create labels and complete the necessary paperwork before gathering all the packages.

Afterwards, the packages are loaded onto trucks or other vehicles to be transported to their intended destinations.

You can track your packages during shipping to monitor their location and estimated delivery time. This feature is useful for both warehouse managers and customers alike.

The shipping process concludes once the packages have been delivered to their intended recipients.

-

Updating data

By updating data, warehouse workers get accurate information about inventory levels.

They regularly enter and change data in a computer system. That data can be the latest stock levels, received shipments, picked items, and other important details.

Updating data also means counting the physical stock and making sure it matches the recorded stock levels. Doing so gives them the correct inventory records and can quickly spot any mistakes.

Updating data also helps workers add more information about the products. For example, they can add descriptions, expiration dates, or details for any product. This makes managing the inventory and predicting demand a lot easier.

What are the functions of warehousing?

-

Storage

Storage is a key job in warehousing, as workers are responsible for keeping goods safe and organised until needed.

Warehouses are designated places that protect goods from bad weather, theft, or damage. In warehouses, products stay in good condition until it’s time to use or sell them.

Storage also means handling goods carefully and stacking them properly. Warehouse staff use the right equipment and methods to store things safely, so they won’t get broken or spoiled.

-

Goods Safety

One of the most important tasks in warehousing is ensuring the safety of goods. Warehouses are crucial in storing and safeguarding goods from potential theft or damage.

Warehouses place a high priority on safety. This is accomplished by implementing various security measures, including cameras, locks, and security guards. In order to ensure that goods are in optimal condition, warehouses regulate temperature, humidity, and other factors. For goods that require specialised storage, designated areas are provided, such as refrigerated rooms or spaces for hazardous materials.

Warehouses prioritise the safety of goods to maintain product condition. When they effectively execute this task, the products meet quality standards and can be sold or delivered as necessary.

-

Price stabilisation

Keeping the prices of products stable and predictable is an advantage that every customer values.

Warehouses play a vital role in stabilising prices by maintaining a balance between the supply of goods and the demand for them. They can store excess products and gradually release them when needed, preventing sudden price drops due to oversupply.

On the other hand, if there is not enough product, warehouses can release some of their stored goods to meet the demand. This stops prices from increasing too much because there is insufficient supply.

Producers can purchase and store a large quantity of goods through warehouses. This can aid in stabilising prices over time, particularly when demand for goods fluctuates during different seasons.

-

Goods Moving

Goods moving is a crucial function of warehousing that involves physically transporting items within the warehouse.

Warehouse workers move goods to ensure they’re properly stored. Proper storage allows them to access any product and rearrange them when necessary easily.

To do so, warehouse workers use equipment like forklifts or conveyor belts, which make the process effortless. However, every item is handled carefully to avoid any damage.

The goal of moving goods in warehousing is to make the best use of space and keep track of inventory levels.

-

Financing

Financing plays a crucial role in warehousing, allowing businesses to use their stored goods as collateral to obtain money.

Warehouses often provide various financing options for businesses. One option is inventory financing, which allows businesses to obtain loans based on the value of their stored goods.

Another option is warehouse receipt financing, where companies can use the warehouse receipt, a document that shows ownership of the goods, as collateral to secure financial assistance. This method is considered secure as the goods held in storage serve as collateral for the loan.

Where to find and advertise available warehouses?

Companies resort to options like online listings, brokers, industrial parks, or simply networking with other professionals to find available warehouses.

Each method has its benefits and downsides, so different companies find different solutions. However, the simplest and most efficient way is using a straightforward platform like KleverCargo.

KleverCargo is a matchmaking platform for logistics and road transport with real-time updates. It allows you to find and post available loads and get the most desirable rates through a bidding system.

One of its features is posting and finding warehouses based on their location and storing preferences.

Find warehouse

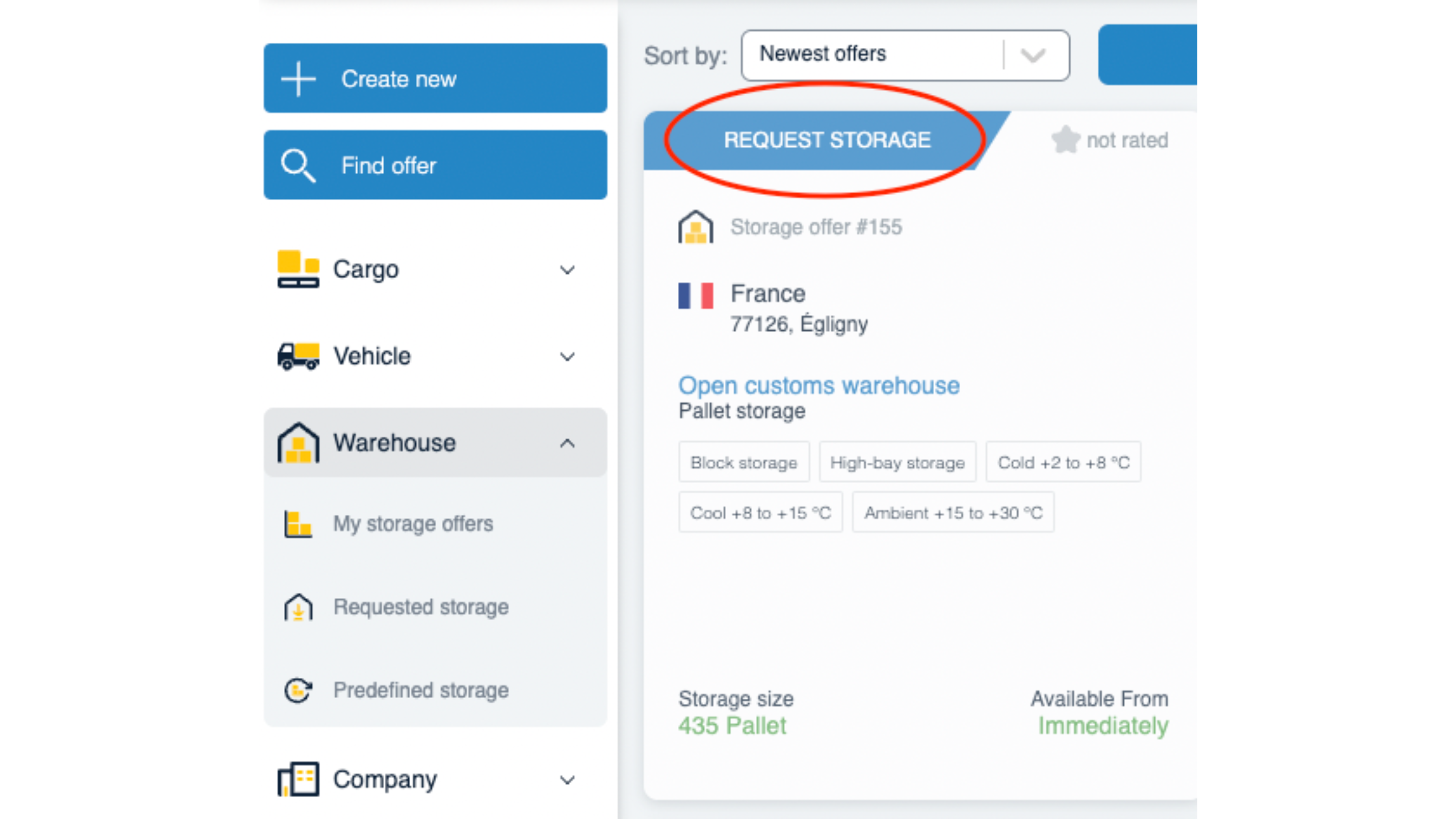

If you want to find the storage space for your cargo, go to the section Find Warehouse to be able to find the list of available storage.

The available storage options will be displayed, and you can simply click on Request storage to learn more about the one you’re interested in.

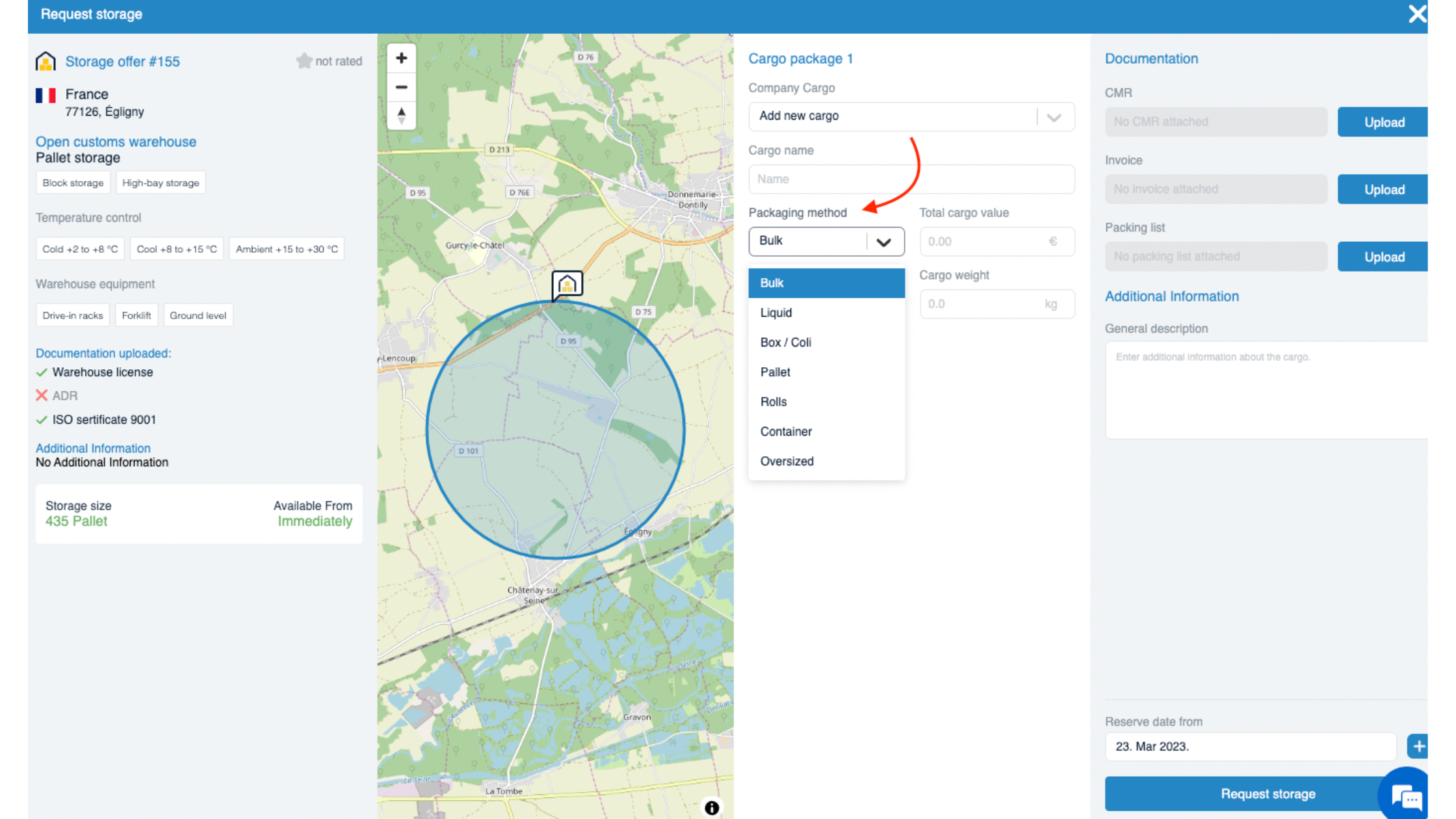

Therefore a new window will be opened with more details:

It’s important to understand that your packing method will affect the required fields. Once you select the suitable offer, you must include the proper documentation on the right side to submit your storage request.

Create warehouse offer

On the other hand, if you want to publish your warehouse offer, the process is as straightforward as it gets. Once you log in to the platform, click the Create new button on the left-hand side of the screen.

When you do so, you’ll be able to choose between three options:

- transport request;

- transport offer;

- storage offer.

Click on the Storage Offer option.

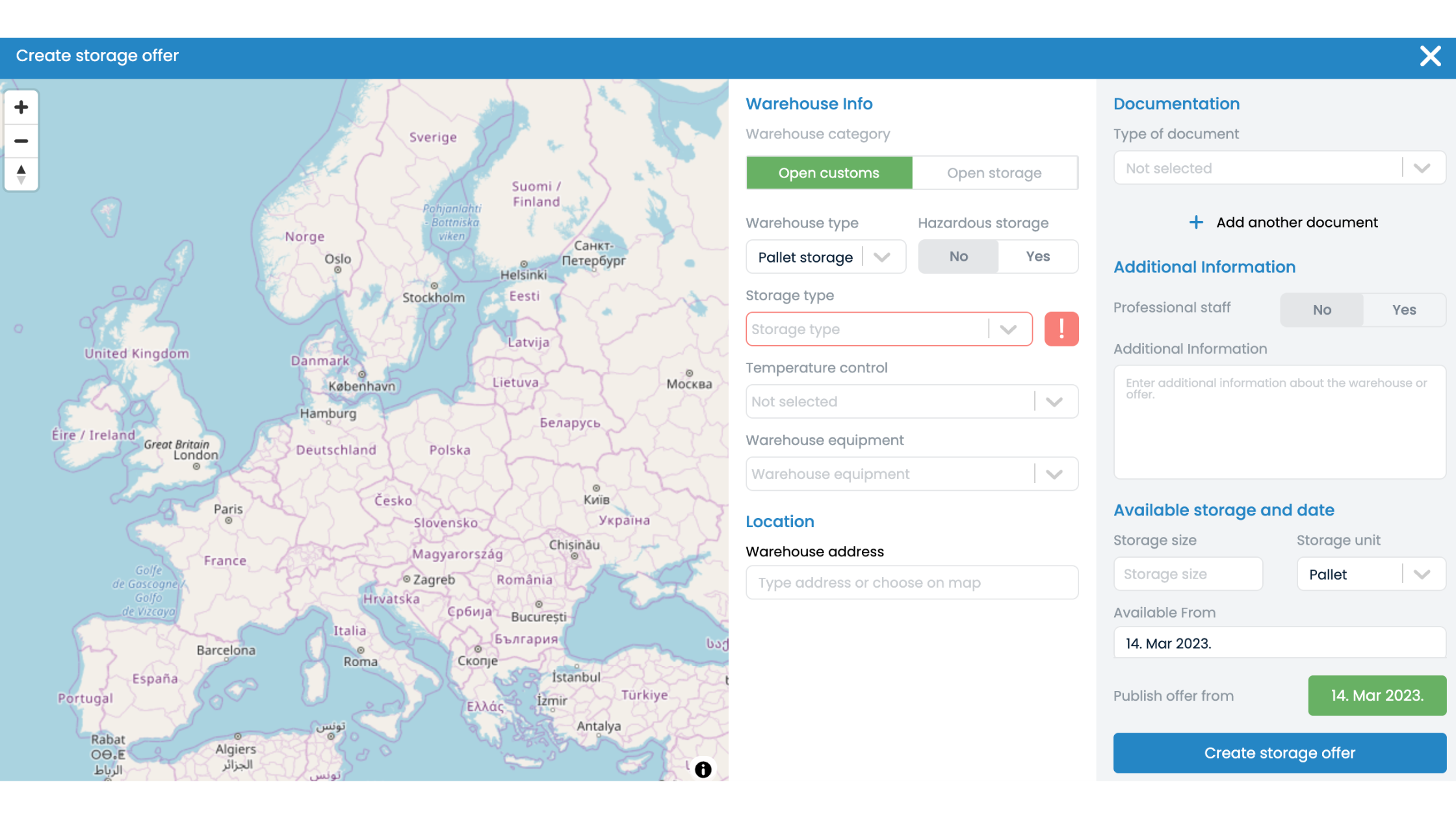

Once you access the menu, you can select the specific criteria for the warehouse. Input information such as the price, storage type, temperature control availability, warehouse equipment, and location. You can also add specific data like availability dates, storage size, or any other relevant information.

The final step is to click the Create storage offer button, and your storage is now active on the platform. You’ll get a notification when someone places a bid which, of course, you can accept or decline.

Utilising this platform allows you to enjoy simplicity without negotiating with brokers or making dozens of phone calls. Everything is centralised on a single platform.

Warehousing – essential link in the supply chain

Warehousing is a crucial link in the supply chain that helps store and manage products. It ensures that goods are ready to be delivered to customers when needed.

It involves various processes to make things run smoothly without any mistakes or delays. Finding a proper warehouse can sometimes be a lengthy process. Still, with a platform like KleverCargo, businesses can simplify that process and easily offer and seek storage solutions.

Ultimately, warehousing is vital in efficient logistics, meeting customer needs, and ensuring an efficient flow of goods from production to consumption