Steel stands as one of the fundamental building blocks of modern life. Its importance is visible in countless industries, ranging from housing and construction to producing mechanical equipment and automotive marvels.

We’ll investigate what goes down in the steel supply chain, but first, we need to understand what steel is and why it is such an important material.

Understand the steel industry

The steel industry covers the entire process of steel production, from extracting raw materials to manufacturing steel products. It’s the driving power of many enormous industries like:

- construction;

- automotive;

- manufacturing;

- infrastructure development.

In the year 2022, the global production of crude steel reached approximately 1.9 billion metric tons. There are a few key players that work together to manage these enormous amounts of material:

- Producers – companies and mills are responsible for turning raw materials into steel products.

- Suppliers – provide materials such as iron ore and coal which are essential to steel production.

- Manufacturers – transform steel into various products used across industries.

- Distributors – bring the steel products to end users.

-

What is steel?

Steel is a versatile alloy composed mainly of iron and carbon. It’s known for its exceptional strength and adaptability. These features make it a core material in various industries such as construction and manufacturing.

Steel primarily consists of iron (Fe) and a small percentage of carbon (C). In various cases, it also incorporates other elements like manganese, nickel, chromium, and more. These additional elements enhance steel’s properties and characteristics, and manufacturers add them to adjust steel for different applications.

The main quality of steel is its adaptability – it can be moulded into countless shapes and sizes, which makes its use in different industries easier.

-

Types of steel

Steel isn’t a one-size-fits-all material. There are numerous types of steel, each with distinct properties. Some of the common types include:

- Carbon steel – it’s mainly composed of iron and carbon, with low to moderate amounts of other elements, and is used in construction and manufacturing.

- Alloy steel – contains additional elements like chromium, nickel, and manganese which enhance corrosion or heat resistance. It’s often found in critical applications, including aerospace.

- Stainless steel – it’s corrosion-resistant, hygienic, and requires little maintenance which makes it ideal for kitchen appliances, medical equipment, and construction.

- Tool steel – known for its hardness and abrasion resistance, tool steel is used for cutting tools and moulds.

Application of steel

As we mentioned, steel is a very versatile material used in a large number of industries.

1. Construction and building industry

Steel is a priceless material in construction. It’s used for beams, columns, and roofing, and provides strength and stability, which offers safety and longevity in buildings. In 2021, the construction and infrastructure sector accounted for 52% of the global steel production usage.

2. Automotive industry

Steel is commonly used in the automotive sector. It forms the chassis, body, and many other components. Its high strength-to-weight ratio enhances vehicle safety and fuel efficiency. The automotive sector represented 12% of worldwide steel consumption in 2021.

3. Manufacturing

In manufacturing, steel is employed for various types of equipment and tools. Its durability and precision are the main perks that manufacturing benefits from.

4. Aerospace industry

Steel’s alloy variants are used in aircraft structures and engines. It can withstand extreme conditions, making it perfect for building aircraft while ensuring flight safety.

5. Energy sector

Steel is vital for constructing power plants, pipelines, and wind turbines. Its corrosion resistance ensures energy infrastructure longevity.

6. Transportation

Trains, ships, and trucks rely on steel for their construction. Its robustness supports the transportation of goods and passengers.

7. Medical equipment

Stainless steel is unmatched for producing medical instruments and devices. Its hygiene, corrosion resistance, and strength are essential in healthcare.

8. Household appliances

Steel is used in kitchen appliances, ovens, refrigerators, and more. Its sleek appearance and durability make it a top choice for homes.

9. Infrastructure

Bridges, tunnels, and other critical infrastructure projects incorporate steel. It ensures the longevity and safety of these structures.

What are the stages in the steel supply chain?

The steel supply chain involves multiple steps that transform raw materials into various steel products. Each stage is unique but crucial to complete the process.

1. Mining and raw material extraction

Mining and raw material extraction is the very first step of the steel supply chain, which sets the stage for the entire steel production.

The process starts with miners, who extract iron ore from large open-pit mines or underground mines. This ore is rich in iron and serves as the primary source material for steel production.

Mining iron ore can have environmental impacts, such as disturbing habitats of animals and water pollution. To make it more sustainable, the mining industry has made efforts to reduce its environmental footprint by:

- reclaiming mined lands,

- implementing water management systems, which prevent water pollution,

- using cleaner technologies.

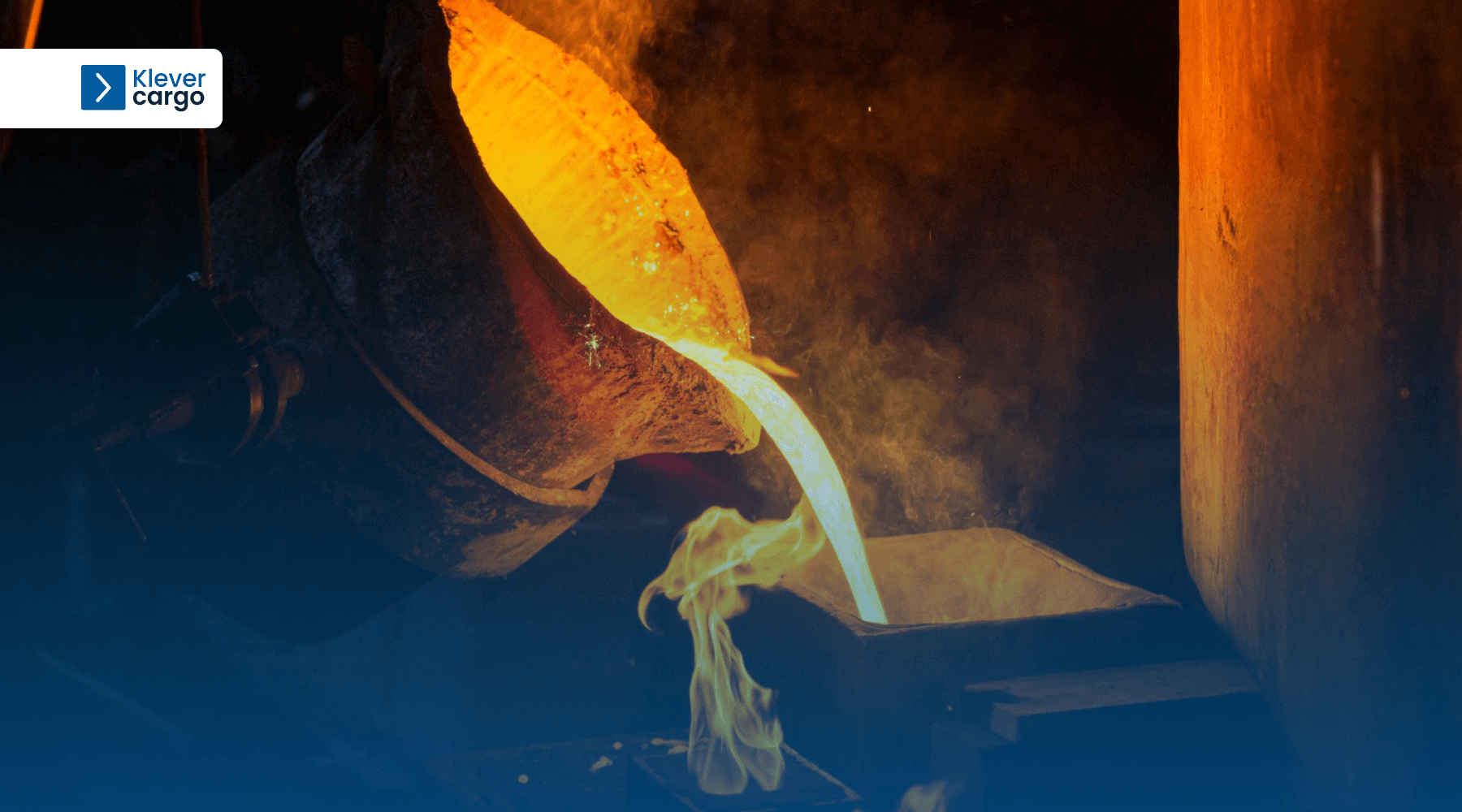

2. Steel production

After extracting raw materials, these materials are transformed into steel. This stage requires a lot of precision and quality control so that the final product meets the quality standards.

Technicians heat the extracted iron ore in a blast furnace, along with other substances like coke and limestone. This process, known as smelting, converts the iron ore into iron, also known as pig iron.

In the next step, the pig iron is refined to remove residue. It may be mixed with other materials to get the desired steel properties. For example, alloying elements may be used to achieve corrosion resistance.

Quality control is critical in steel production. Controlling technicians use advanced testing methods to ensure that the steel meets the required standards. With proper quality control, professionals can solve any issues before the production proceeds to the next steps.

3. Steel manufacturing

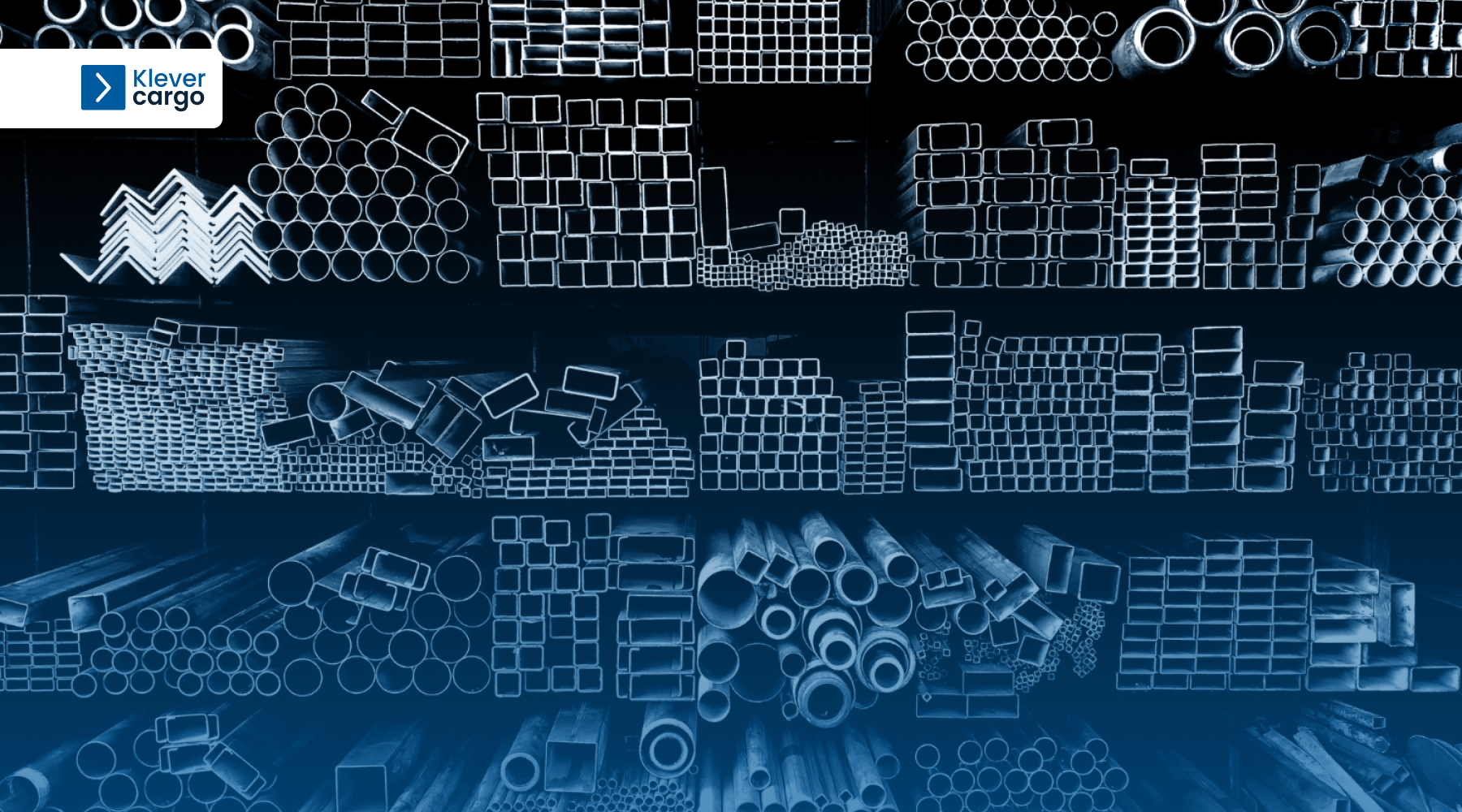

Once steel is produced, it goes through the steel manufacturing stage. In this stage, the steel is processed into various products with different purposes.

Steel is often rolled into different shapes, like coils or plates. To get this shape, the manufacturers pass it through large rollers, which flatten it into the desired form.

Then, the steel can be cut and shaped to create specific products. For example, pipes and tubing are formed by cutting and shaping flat steel into cylindrical structures.

Also, manufacturers can shape steel using various different methods, like bending or welding, which help them create products for multiple usages.

Common steel products

- Steel coils – long sheets of steel which are wound into a roll are usually used in automotive and construction.

- Steel sheets and plates – their application ranges from household appliances to heavy machinery.

- Pipes and tubing – cylindrical products which convey liquids or gases are mostly used in construction, plumbing, and the transportation of fluids.

- Structural shapes (beams, channels, angles) – these shapes of steel are primarily used in construction, as they provide structural support for buildings and infrastructure.

- Wire and rods – they have numerous applications, from reinforcement in concrete structures to electrical wiring and fencing.

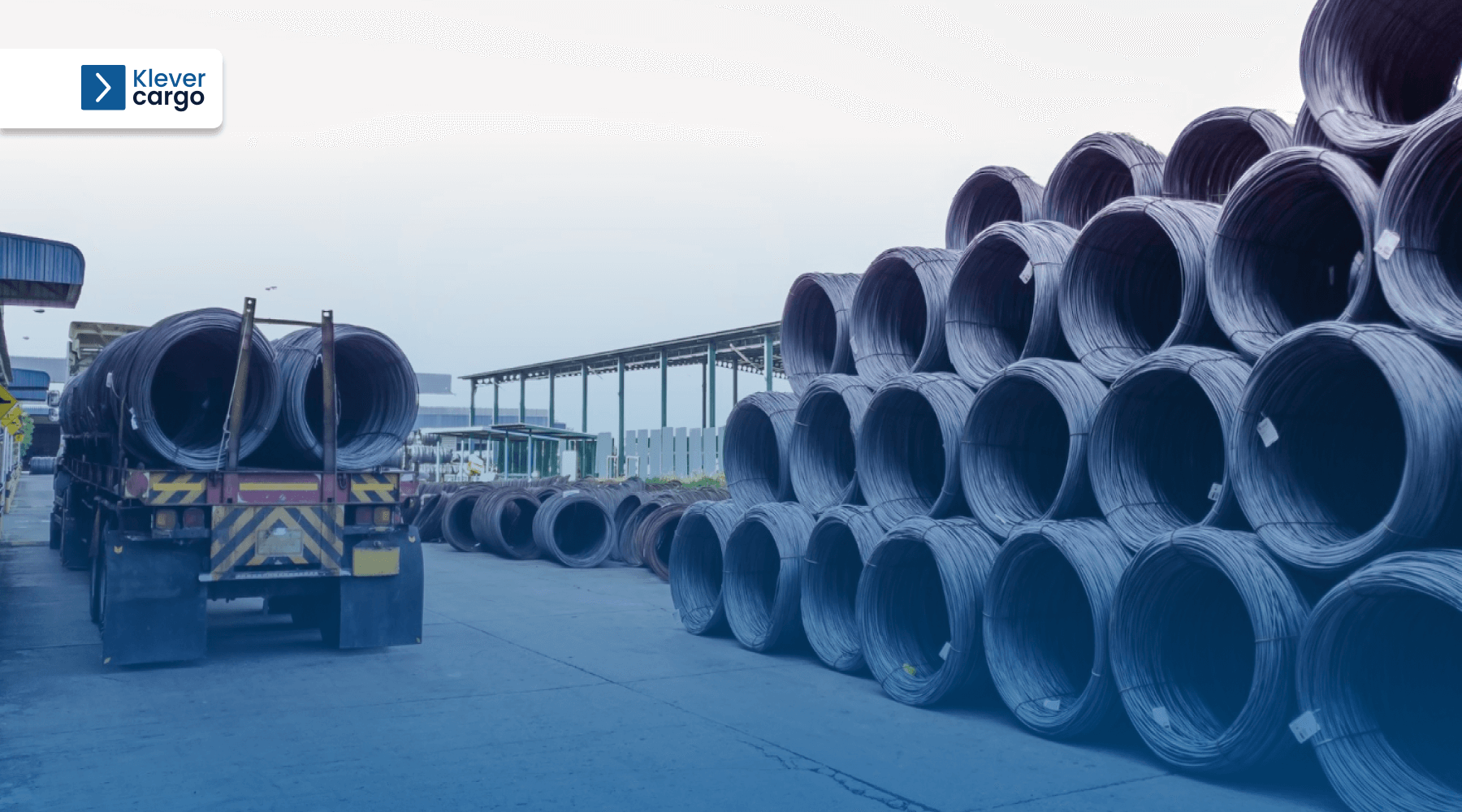

4. Logistics and transportation

The logistics and transportation of steel is a critical stage in the steel supply chain, and it comes with its unique challenges. Steel, being heavy and hard to manoeuvre, demands precision and care in its transportation.

-

Challenges in steel transportation

Firstly, steel products are hefty and can vary in size, which poses challenges in finding suitable transportation methods, especially for oversized or overweight items.

Also, handling steel is another challenge in its transportation. It requires specialised equipment and experienced personnel to ensure safety during the transportation process. If not, damage and accidents can easily happen.

Furthermore, transporting steel can be costly, especially considering costs like fuel consumption and handling equipment. Finding cost-effective transportation solutions is a priority for businesses.

Finally, the steel industry must follow strict regulations, including weight limits and dimensional restrictions. Non-compliance can lead to legal issues and fines.

To address these challenges and ensure reliable and efficient transportation of steel products, companies can turn to solutions like KleverCargo, a digital freight exchange platform.

-

Weight and size

On the KleverCargo platform, transportation solutions are readily available for oversized and heavy cargo. That makes it a one-stop solution for businesses transporting steel products with exceptional weight and size requirements.

KleverCargo partners with carriers and logistics providers equipped to handle oversized and heavy cargo. These carriers have the necessary equipment to safely and efficiently transport steel products of varying dimensions.

The platform also allows businesses to specify the weight and size of their cargo.

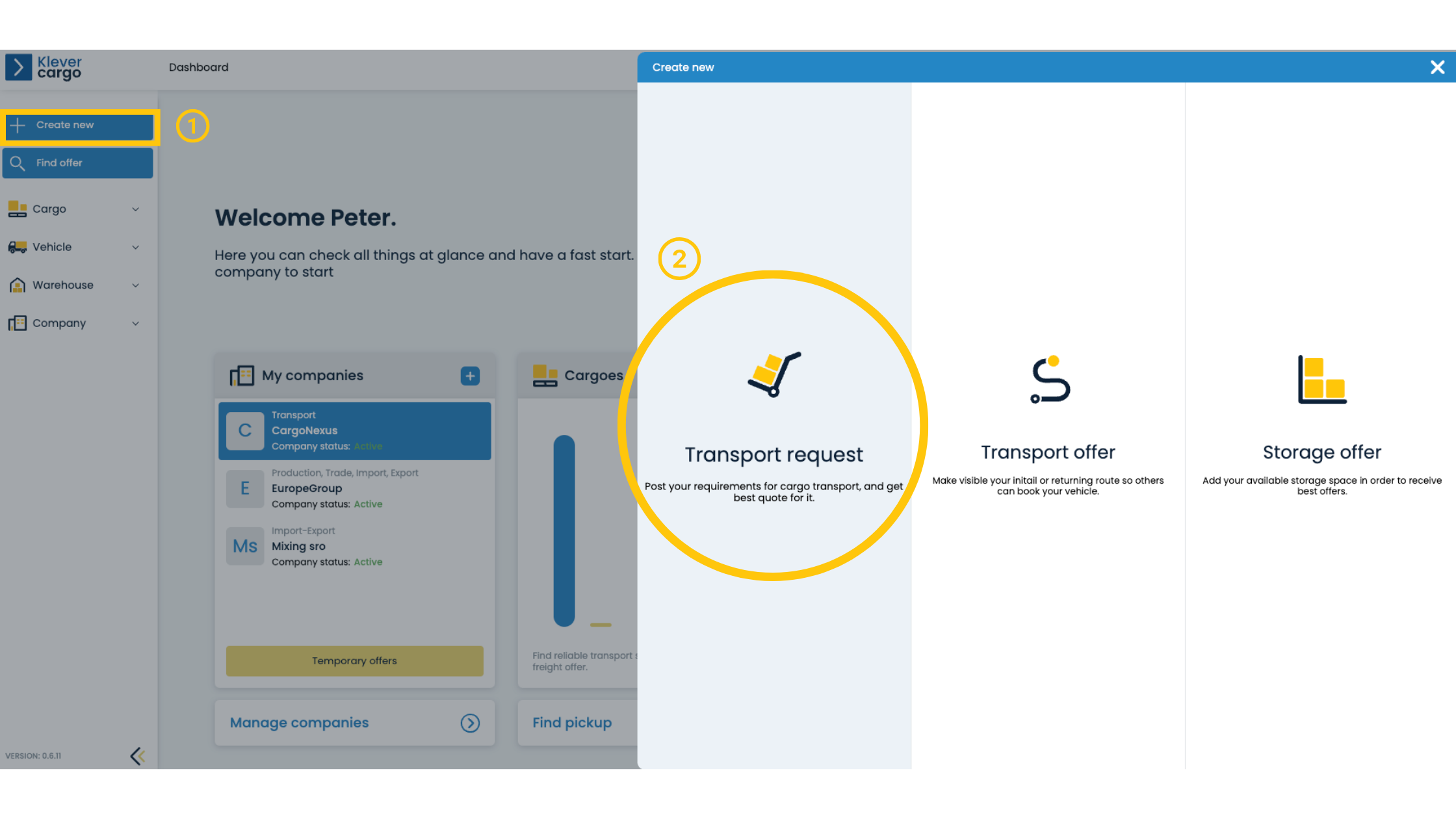

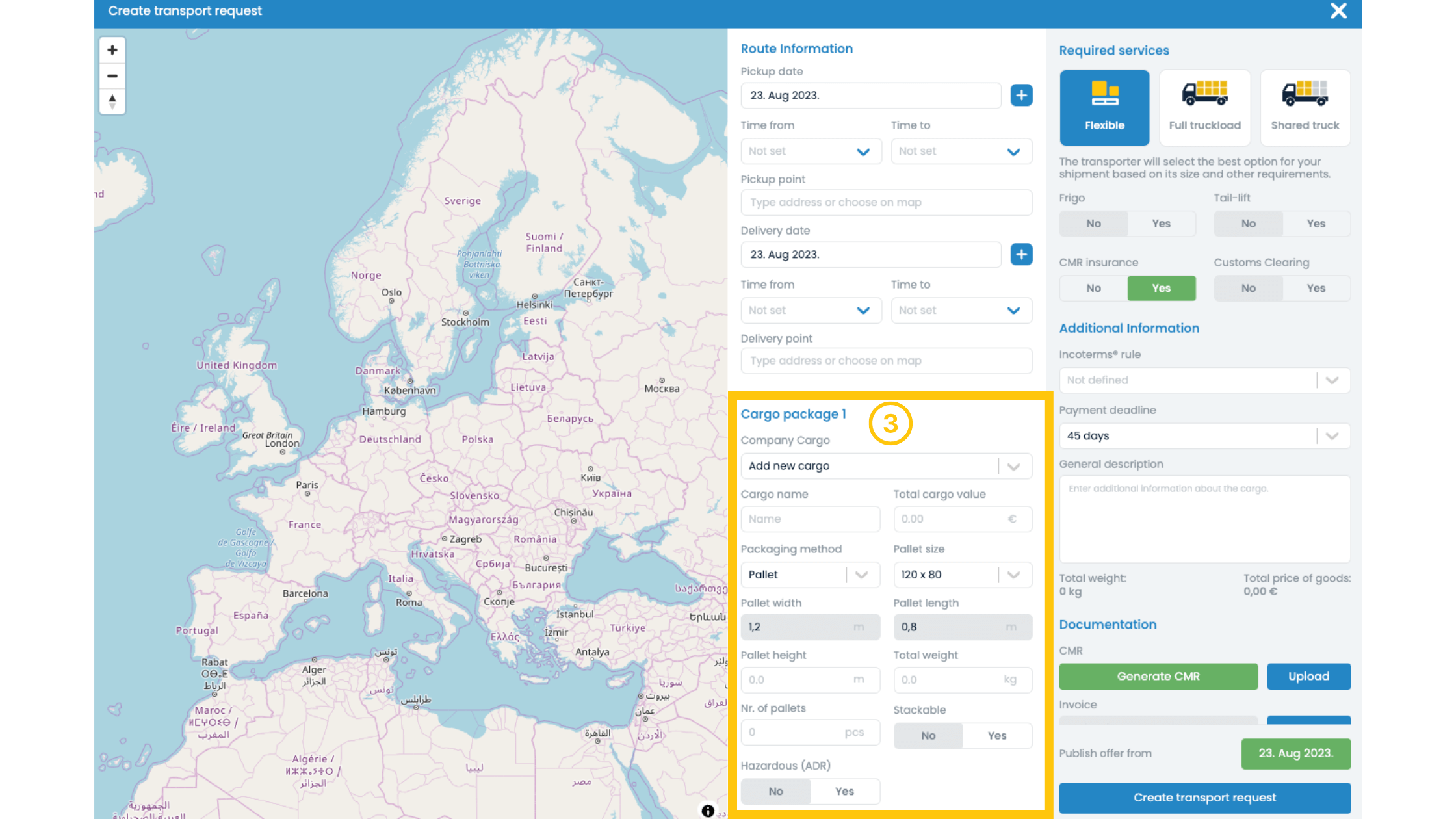

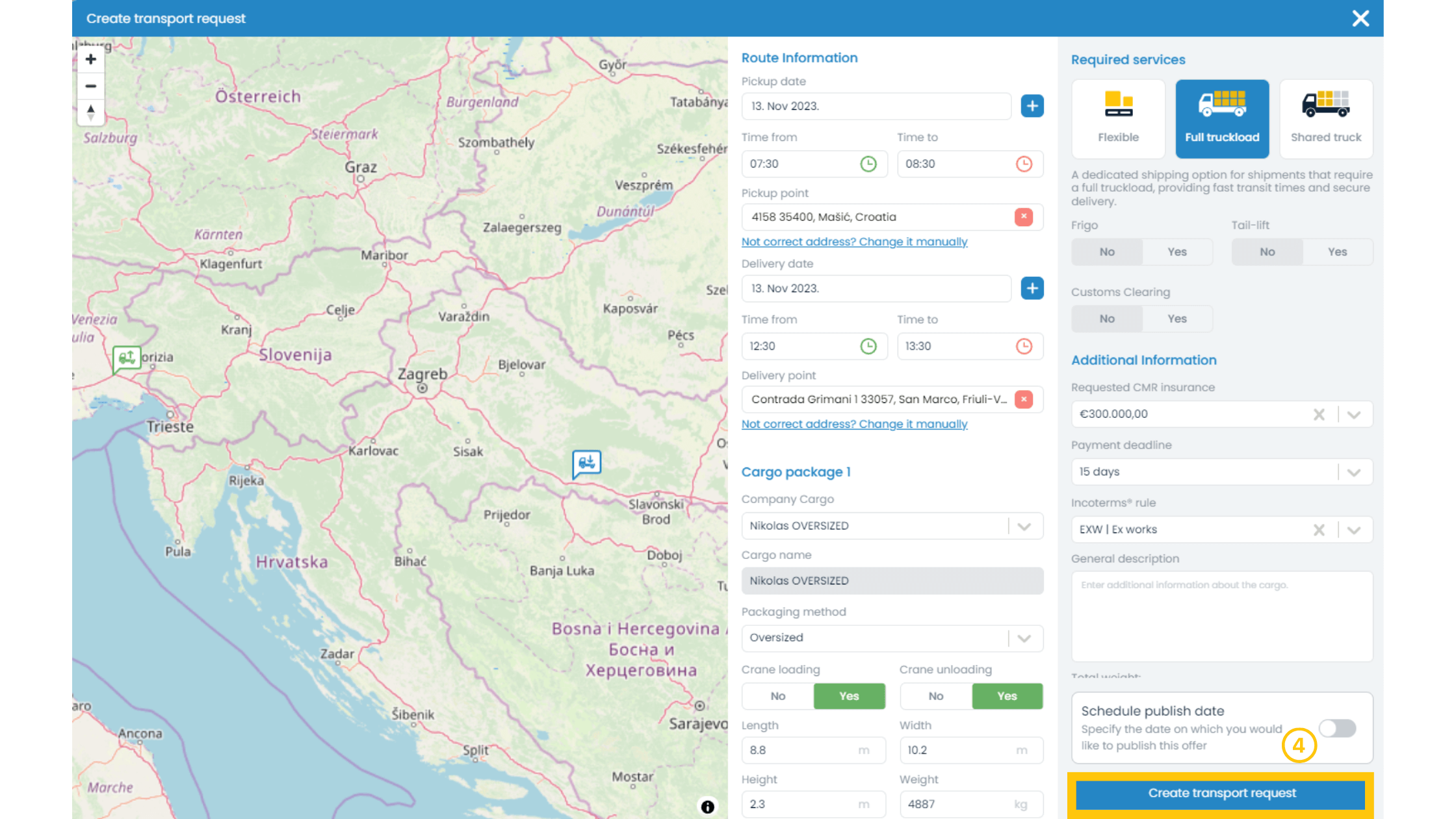

All you have to do is:

1. Register or log in (if you already have an account), and click on + Create new.

2. Then, choose Transport request.

3. Fill in the blanks – pay close attention to give precise dimensions of your cargo.

4. When you’ve given all the necessary information, click on Create transport request.

The platform’s carriers have experience in handling oversized loads, which ensures that the transportation process is not only safe but also efficient. Thus, with this feature, you won’t need to worry whether the carriers are capable of meeting your unique transportation needs.

-

Safety and handling

KleverCargo prioritises the safety and proper handling of cargo, including steel products. The platform offers an extra layer of security through its verified carriers with transparent ratings and reviews.

KleverCargo thoroughly inspects carriers and logistics providers to ensure they meet industry standards. The point of this assessment is to make sure only reliable companies get verification.

In addition, users of the platform have the opportunity to rate and review carriers based on their experiences. These transparent reviews provide valuable feedback, helping others make informed choices when selecting a carrier.

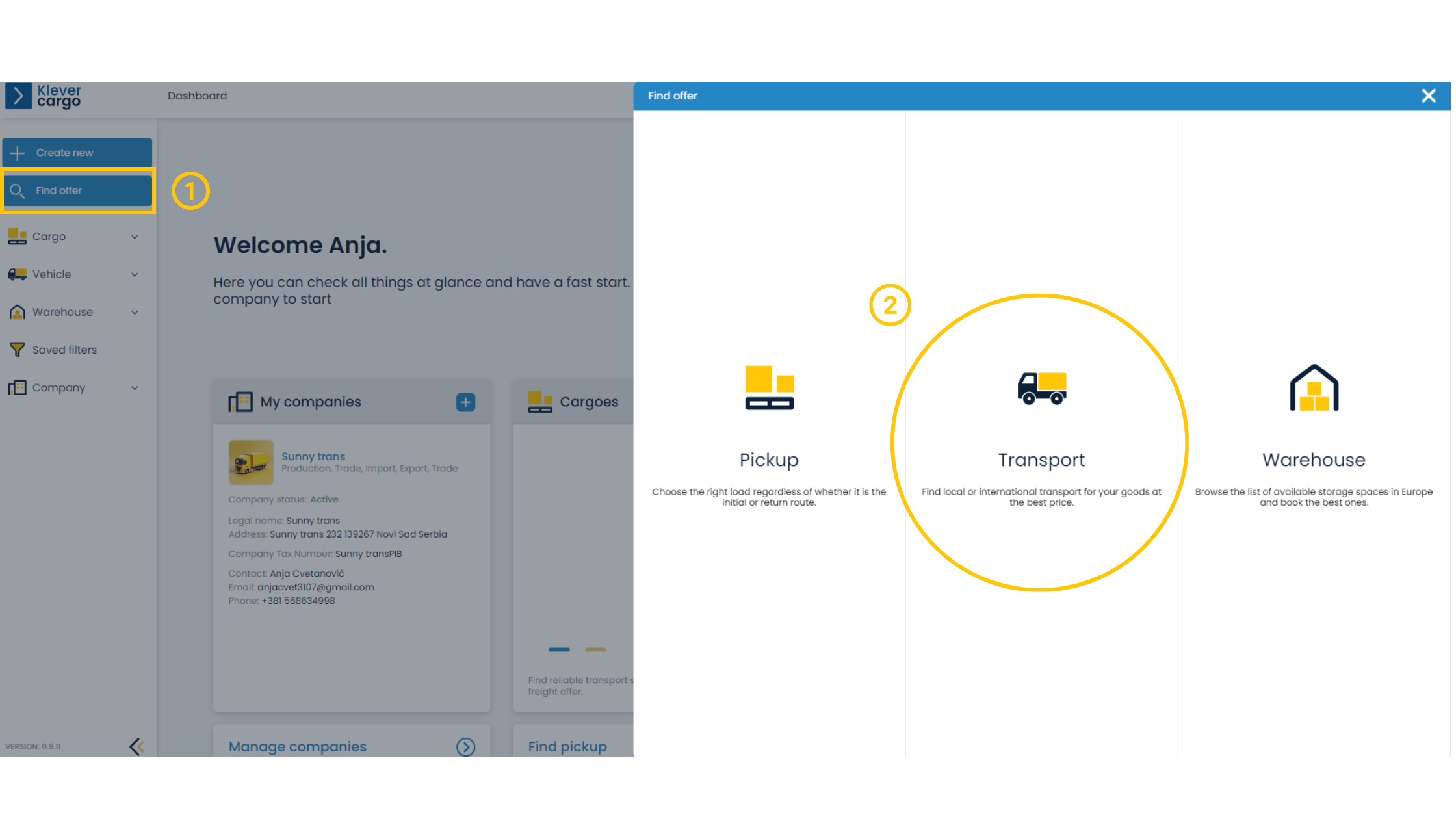

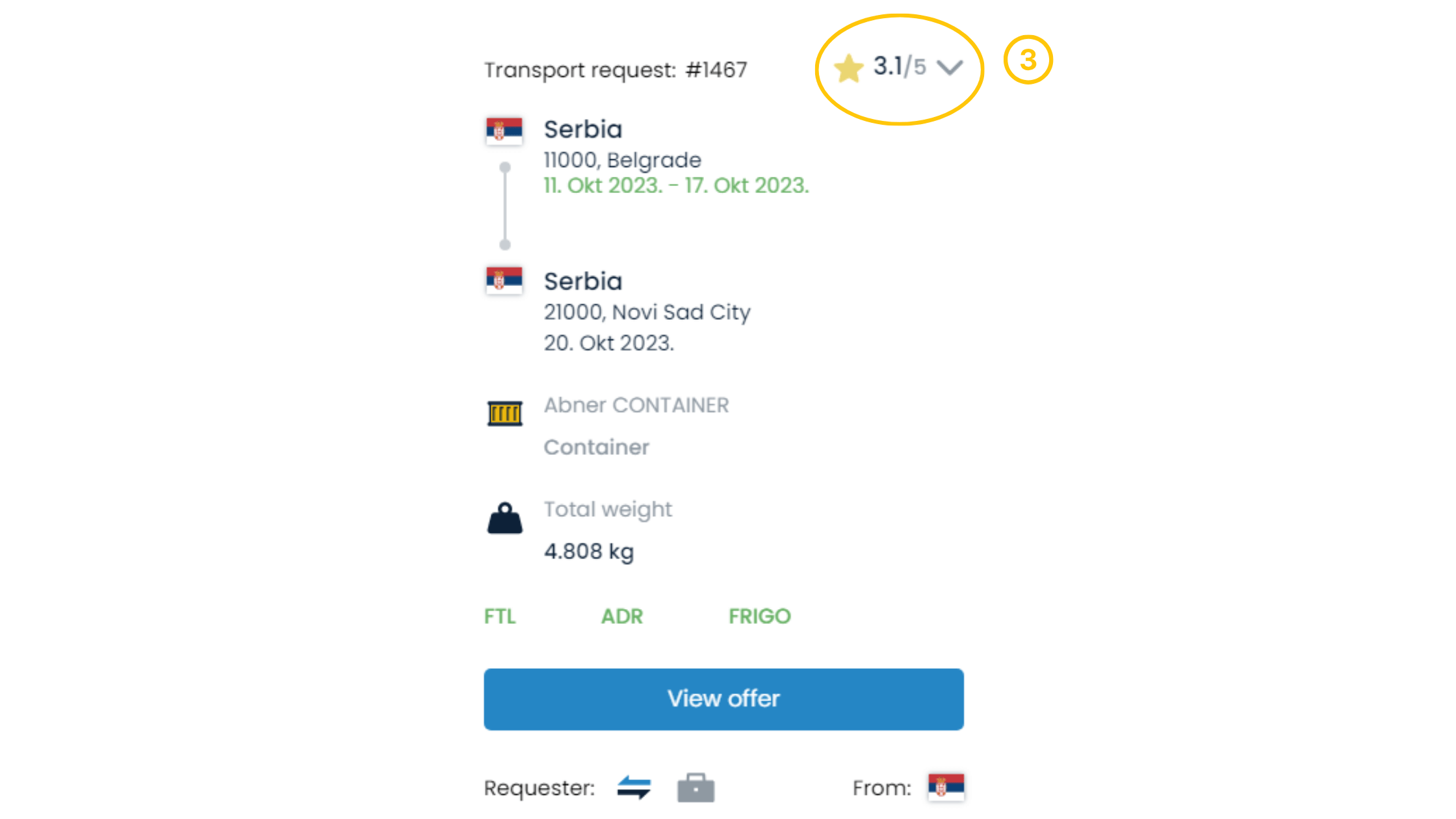

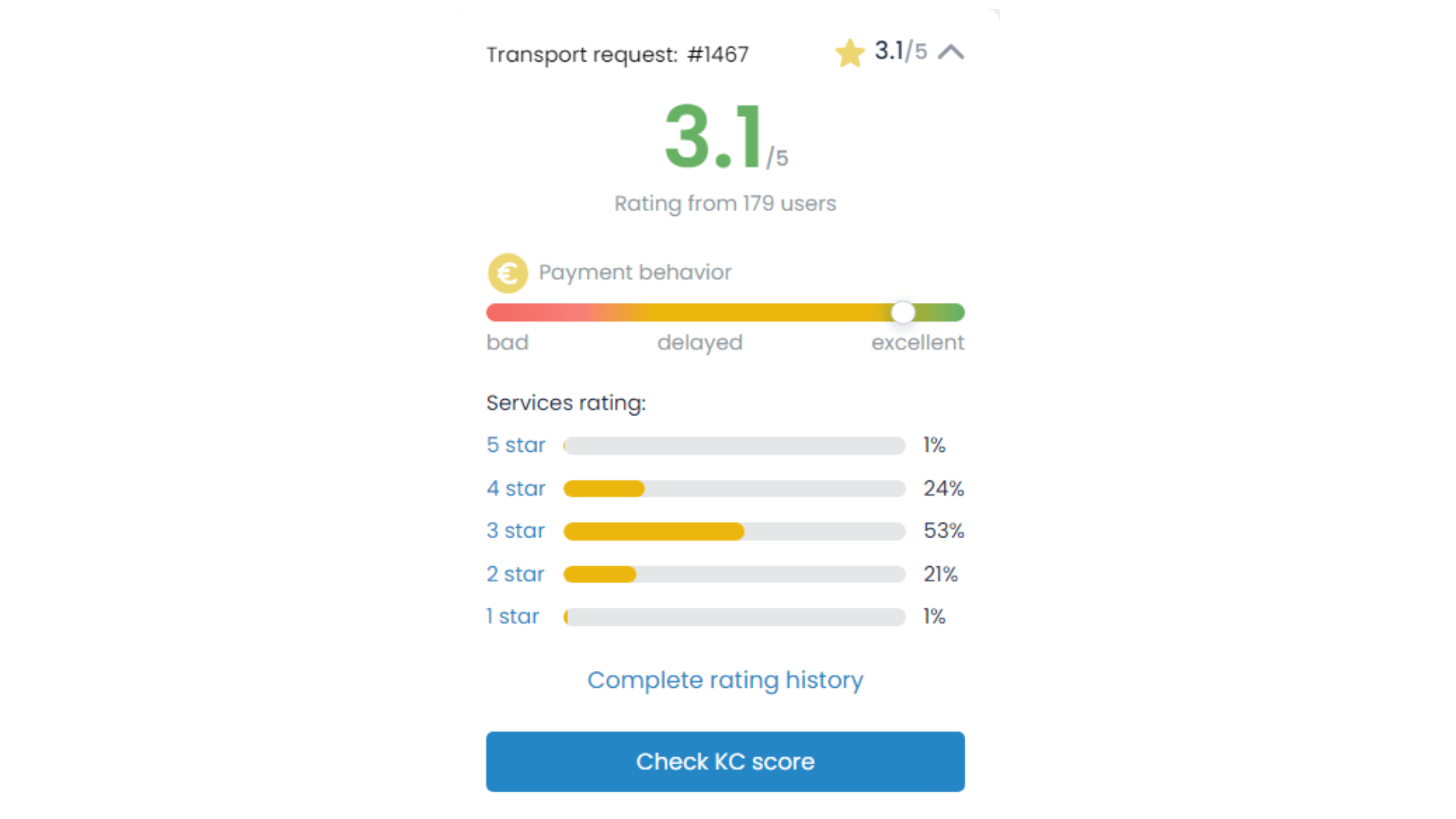

To check out user scores, you need to:

1. Register or log in (in case you already have an account) and click on Find offer.

2. Then, choose Transport.

3. When the offers appear on your screen, check out the upper right corner – there you can see the rating of the user.

4. Click on it and the rating will expand, allowing you to get more insights into other users’ experience with that company.

-

Cost efficiency

Transporting steel can indeed be costly, but KleverCargo offers a cost-efficient solution through its bidding and price range options.

Businesses can list their transportation requirements on the platform, and carriers can then submit bids to win the contract. This environment results in competitive pricing, allowing businesses to choose the most cost-effective option.

The whole process is very simple – here is what it looks like:

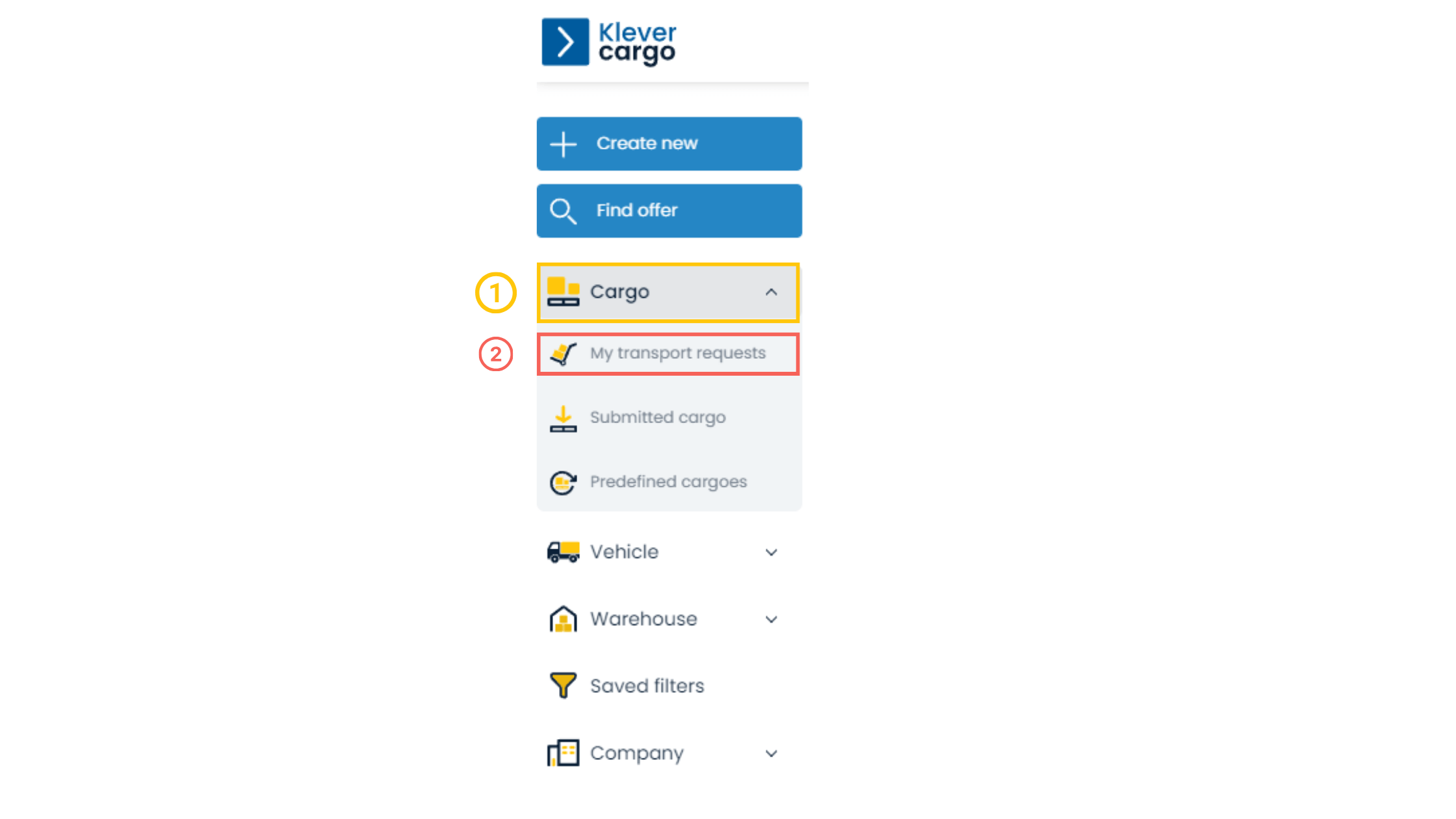

1. Register or log into your account (if you already have one). Then, on the left side, look for the button Cargo. Click on it and select My transports requests.

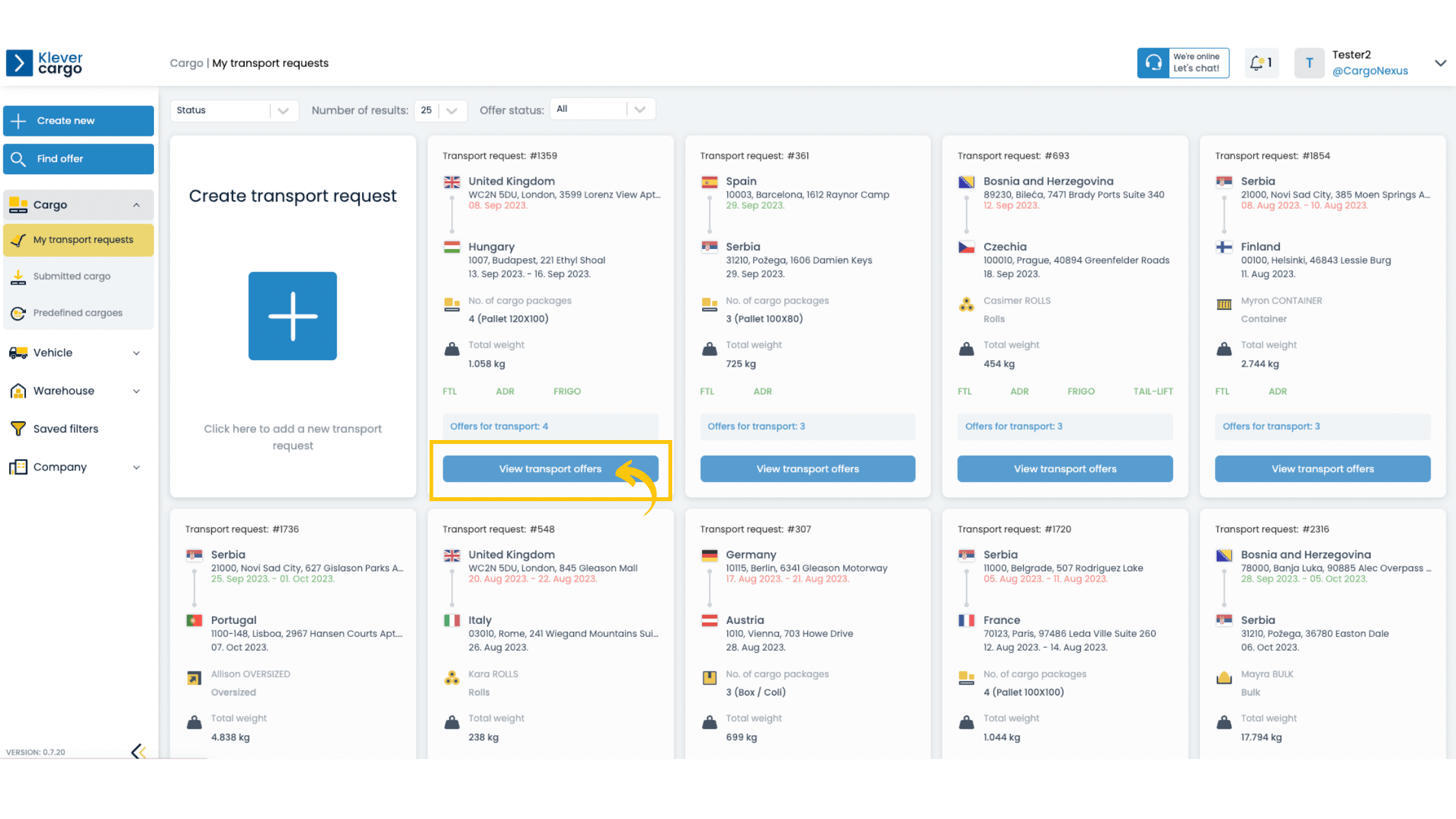

2. Then, all your requests will appear. In order to see transporters’ offers, click on View transport offers.

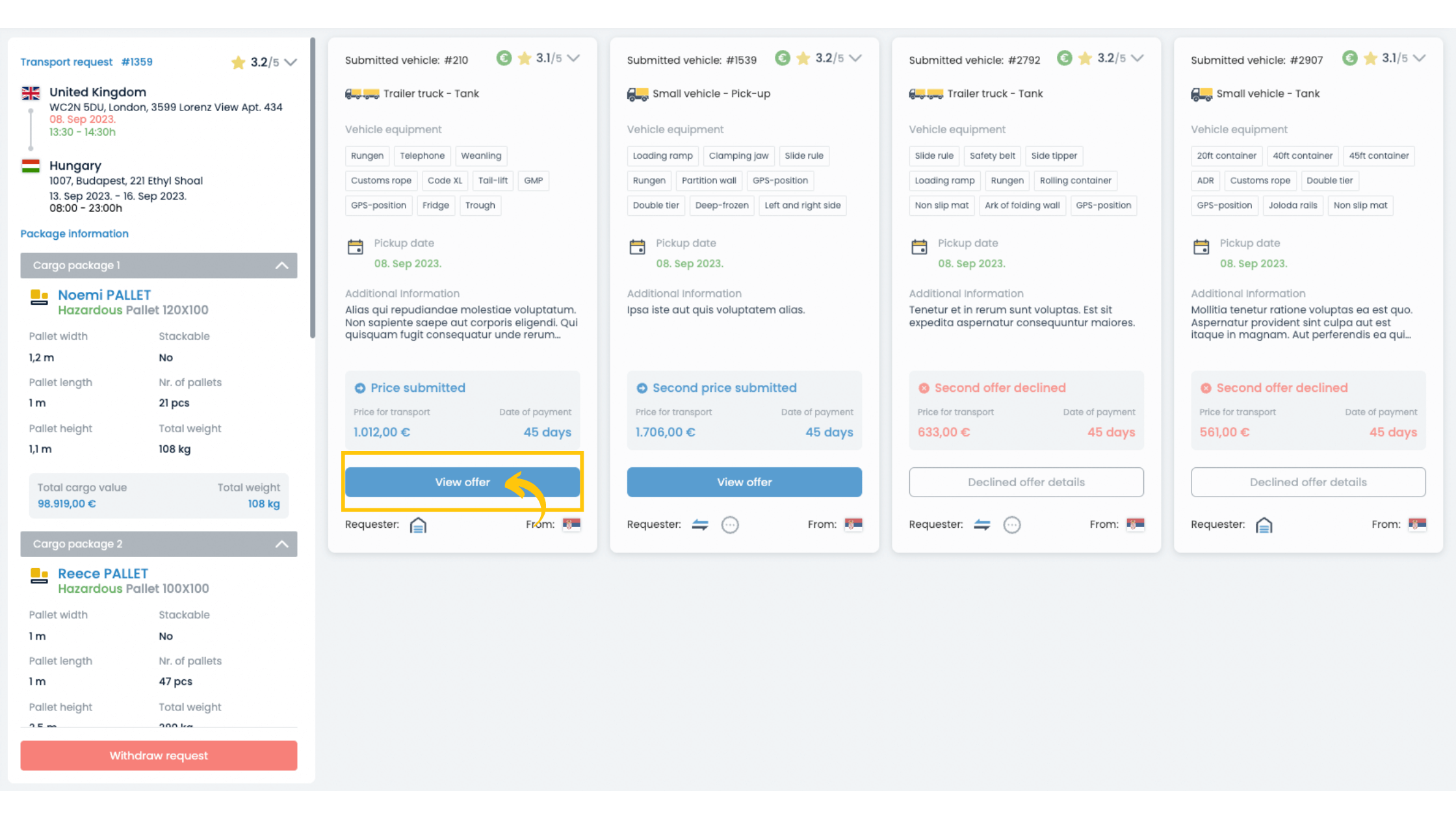

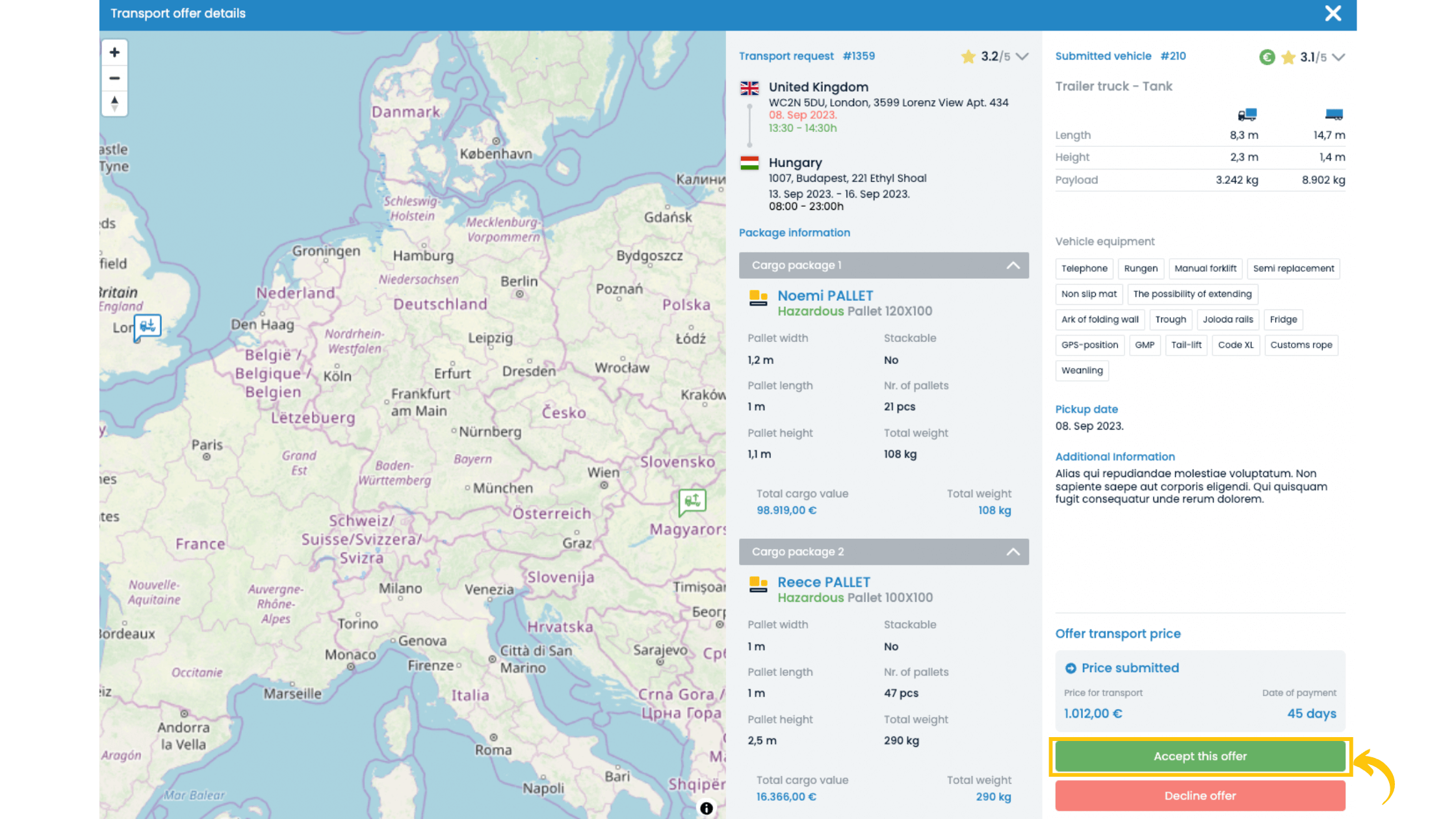

3. Now, when you can see all the offers for your transport request, choose one and select View offer to see more details.

4. Check out the suggested price and if you’re ready to accept it, choose the green button Accept this offer.

With this flexibility of the KleverCargo platform, you can always find cost-effective transportation solutions, without much stress.

-

Regulations and compliance

The steel industry must follow strict regulations, including weight limits, dimensional restrictions, and environmental regulations. Specific to Europe, these regulations are essential:

- Weight limits – vary by country, but a common standard is 40 metric tons for trucks.

- Dimensional restrictions – also vary by country, but the maximum length is usually up to 18.75 metres, maximum height typically ranges from 4 to 4.5 metres, while width can be around 2.5 metres.

If the cargo weighs more than this, carriers must obtain special permits, which allow the transportation of oversized cargo only on the specified routes.

5. End users

The final stage of the steel supply chain involves distributing steel products to end users. Steel manufacturers and suppliers often have well-established distribution networks to deliver steel products to their clients.

Steel products find their way to end users via various transport modes. These modes include trucking, rail transport, and even maritime transport. The method will depend on the requirements of end users.

Quality control measures are critical to guarantee that the steel products are in perfect condition when they reach the end users. To achieve that, workers need to carefully load and unload to prevent damage during transportation.

The efficient and reliable distribution of steel products to end users is crucial to fulfilling the demands of industries that rely on steel for their projects.

Sustainability and environmental consideration inside the steel supply chain

Companies are paying more and more attention to sustainability and environmental considerations in the steel supply chain. Here are some of the most interesting eco-friendly initiatives within the industry:

-

Recycling

One of the most significant sustainable practices in the steel supply chain is recycling. Steel is highly recyclable; what’s more, recycled steel reduces the need for virgin resources. Thus, it saves energy and lowers carbon emissions.

-

Energy efficiency

Steel manufacturers keep improving energy efficiency in their operations. They optimise furnaces and use technologies like electric arc furnaces, which consume less energy compared to traditional blast furnaces.

-

Water management

Sustainable water management practices, like reusing and recycling water in steel production, reduce water consumption. That minimises the environmental impact on water resources.

-

Reduced emissions

The steel industry is actively working to reduce emissions through cleaner production processes in the production of coke and coke oven gas.

-

Certification and standards

Initiatives like the ResponsibleSteel set criteria for sustainable steel production. That ensures that steel products meet environmental and social standards.

In summary

The steel supply chain is a layered process, from the extraction of raw materials to the distribution of steel products to end users. Understanding these stages and challenges in this process is necessary to ensure the continuous flow of this valuable material. Additionally, embracing sustainability initiatives within the steel industry is what makes a greener and more responsible future.

To simplify and optimise the transportation of steel products, we recommend considering the KleverCargo platform. With its tailored solutions for oversized cargo, transparent and reliable carriers, and cost-efficient options, KleverCargo offers a seamless and eco-friendly way to meet your steel transportation needs. Register on KleverCargo now to streamline your steel supply chain and enhance your logistics operations.